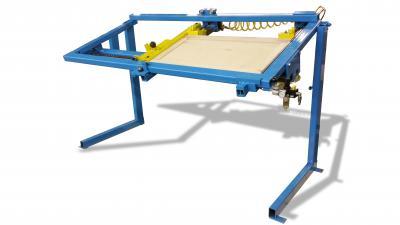

Features:

#717A-6-M: 6′ Miter Door Clamp Side:

- 26″ x 62″ Maximum capacity.

- Includes (2) Vertical Clamps & (2) Horizontal Clamps.

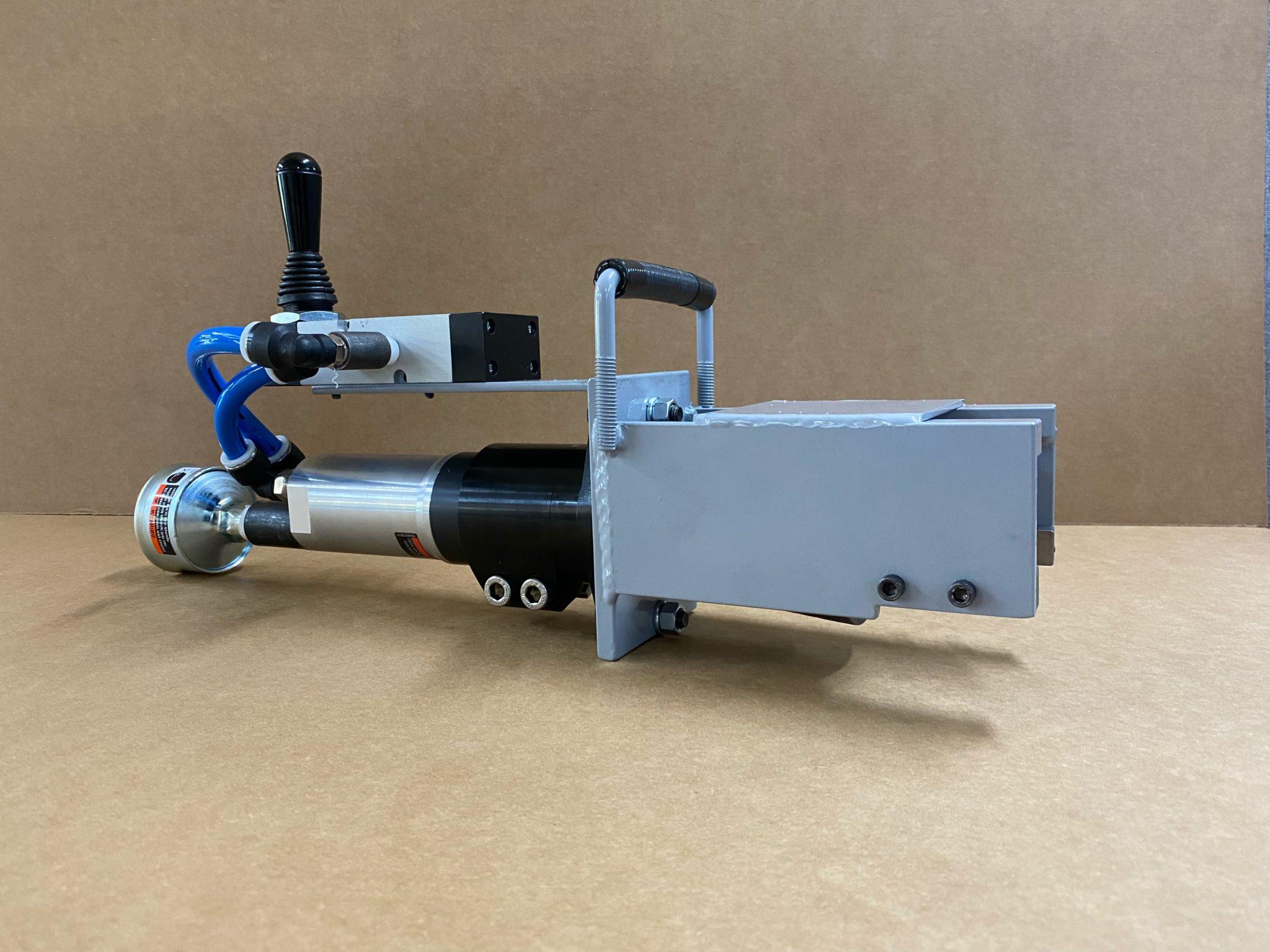

- Each clamp includes the JLT Dial Control System for fine adjustments, which is simple and easy to use.

- This innovative Dial Control System allows for adjustments in BOTH directions while the door is under clamping pressure

- Precise and Accurate Squaring for both Miter and Stile & Rail Cabinet Doors

- Precisely Clamp and Square MDF or HDF Doors too!!

#79F-8-PC: 8′ Wide Panel Clamp Side:

- (5) total gluing levels

- Includes (18) 3 1/2″ High Jaw 40″ opening clamps (52″ Clamps Available upon Request)

- Innovative, Space Saving Feature that allows the Clamps to be hung Vertically when not in use

- Edge Glue and Face Glue a variety of solid wood components

- 100% steel tubular construction that Creates a Flat and Even Work Area for Clamping Panels

Machine Footprint: 97″L x 70″H x 64″W

(Additional Information Below)